In the dynamic and demanding world of industrial operations, the efficiency of movement and transportation within manufacturing environments is critical. Heavy duty caster wheels play a pivotal role in the seamless mobility of heavy machinery and equipment. Recent innovations in caster wheel technology have significantly enhanced the functionality and reliability of these indispensable components. This blog explores the myriad benefits brought about by these advancements, particularly emphasizing the contributions of caster wheel manufacturers in India.

Enhanced Durability and Load Capacity

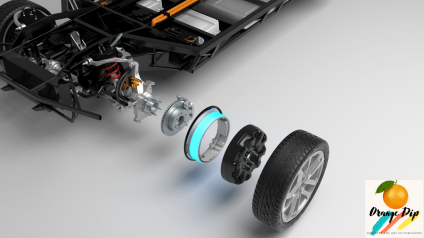

One of the most significant advancements in heavy duty caster wheel technology is the improvement in durability and load-bearing capabilities. Modern materials and innovative design techniques have led to the development of wheels that can handle significantly heavier loads without compromising the integrity of the wheel. This is particularly beneficial in industries such as construction, manufacturing, and warehousing where heavy machinery and goods are frequently moved.

These new materials not only support heavier loads but also resist wear and tear more effectively, thereby extending the lifespan of the wheels. The use of high-performance polymers, reinforced steels, and engineered composites in caster wheels ensures that they can withstand rigorous use in diverse environments, from extreme temperatures to chemically aggressive areas.

Improved Maneuverability and Ergonomics

Recent innovations have also focused on enhancing the maneuverability of heavy duty caster wheels. Advanced swivel technology allows for smoother and more precise steering, which is crucial in tightly packed industrial spaces where precise movement is necessary to navigate through narrow corridors and around sharp corners. This improved maneuverability reduces the effort required to operate the equipment, thereby enhancing ergonomic safety for workers who handle heavy loads daily.

Moreover, the incorporation of better shock absorption systems within the wheels helps in smooth transportation over uneven surfaces, which minimizes the risk of damage to sensitive equipment and reduces vibration that could lead to fatigue in workers.

Increased Floor Protection

Modern heavy duty caster wheels are designed to be floor-friendly despite their capacity to carry heavy loads. Innovations in wheel tread materials and design mean that these wheels distribute weight more evenly and exert less pressure on floor surfaces, thus preventing damage like scuffs, marks, or gouges on floors. This is especially important in facilities where maintaining floor integrity is essential, such as in pharmaceutical or electronic manufacturing plants.

Corrosion Resistance and Chemical Durability

With the integration of advanced coatings and materials that are resistant to corrosion and chemicals, heavy duty caster wheels are becoming increasingly suitable for use in harsh environments. This includes settings prone to moisture, chemical spills, or corrosive substances. The use of stainless steel, zinc coatings, and specialized plastics ensures that the wheels can endure such conditions without degradation, thereby maintaining their functionality and appearance over time.

Sustainability and Cost-Effectiveness

Advancements in manufacturing processes have also led to more sustainable production methods for heavy duty caster wheels. Caster wheel manufacturers in India are adopting practices that reduce waste and energy consumption during production. Additionally, the increased durability and maintenance ease of these wheels ensure that the need for frequent replacements is curtailed, which significantly cuts down the long-term costs and environmental impact of sourcing new materials.

Contribution of Indian Manufacturers

Indian manufacturers have been at the forefront of adopting these technological innovations. With a focus on research and development, these manufacturers are not only improving the quality and performance of caster wheels but are also tailoring solutions to meet specific industrial needs. Their contribution has been crucial in making heavy duty caster wheels more reliable, efficient, and suited to the challenging demands of modern industries.

Conclusion

The innovations in heavy duty caster wheel technology represent a significant leap forward in industrial mobility solutions. These advancements have made it possible to enhance operational efficiency, safety, and cost-effectiveness, thereby supporting the growing demands of various industries. As technology continues to evolve, the future of heavy duty caster wheels exporters in India looks even more promising, with continuous improvements expected to drive further benefits across global industrial landscapes.